Hard Maple:

Unlike most other hardwoods, the sapwood of Hard Maple is most commonly used rather than its heartwood. Sapwood color ranges from nearly white to an off – white creamy color – at times having a reddish or golden hue. The heartwood tends to be a darker reddish brown.

Soft Maple:

The term “Soft Maple” does not refer to any specific species of maple, but rather, it is a broad term that includes several different species of maple. “Soft Maple” is merely used to differentiate these species from Hard Maple.

Cherry:

Cherry is known for being one of the best woods for workability. It is stable, straight grained and machines well. The heartwood is a light pinkish brown upon harvest, darkening to a reddish brown with time and upon exposure to light. Sapwood is a pale yellowish color.

Red Oak:

Pale reddish brown, sapwood darker, heavy, hard, strong, coarse-grained.

Ash:

Among the most common species of ash commercially available, some basic divisions can be made. Fundamentally, it is between White Ash (fraxinus americana) and Black Ash (fraxinus nigra). White Ash tends to have a lighter heartwood color, and wider spaced growth rings. By contrast, the heartwood color of Black Ash tends to be slightly darker, and the growth rings are typically much closer together.

Walnut:

It is a dense wood that nails, machines and glues well. It bends, manufactures and stains well. The polished finish can be exceptional. It is one of the scarcest native hardwoods. Walnut is steamed in order to enhance the chocolate brown heartwood and darken the sapwood. With distinctive grain patterns, it is heavy, hard and stiff with a high shock resistance.

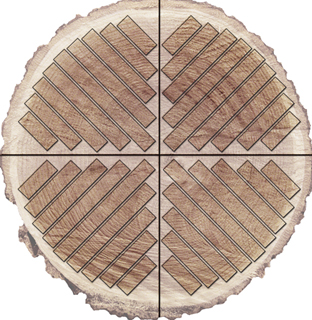

Quarter-Sawn:

AVAILABLE IN ALL SIZES FROM 4/4 (25mm) through 12/4 (80mm)

Plain sawn, also commonly called flat sawn, is the most common lumber you will find. This is the most inexpensive way to manufacture logs into lumber. Plain sawn lumber is the most common type of cut. The annular rings are generally 30 degrees or less to the face of the board; this is often referred to as tangential grain. The resulting wood displays a cathedral pattern on the face of the board.

Quarter sawn wood has an amazing straight grain pattern that lends itself to design. Quarter sawn lumber is defined as wood where the annular growth rings intersect the face of the board at a 60 to 90 degree angle. When cutting this lumber at the sawmill, each log is sawed at a radial angle into four quarters, hence the name. Dramatic flecking is also present in red oak and white oak.